Collapsible Tubes Filling Machine, Collapsible Tubes Sealing Machine

Features:

- Manually tube feeding, automatic registration mark identifying, filling, sealing with coding, end trimming, tube out feeding.

- Cam indexing system could position precisely for ten working stations.

- Adopts ultrasonic sealing technology, no need warm up time, more stable and neat sealing, no distortion and low reject rate less than 1%.

- Independent R & D for digital ultrasonic automatic tracking electrical control box, no need manual adjust the frequency, with power auto compensation function, avoiding the reduction of power after long time use. Could freely adjust the power based on tube material and size, stable and minimum the fault rate, extend the life span than the normal electrical box.

- PLC with touch screen control system with alarm system, could directly view the alarm information on the touch screen, could locate the problem and solve immediately.

- Made of 304 stainless steel, acid and alkali resistance, corrosion resistance.

- No tube, no fill, no tube, no seal function, reducing the machine and mould loss.

- Adopts Anti-dripping filling nozzle.

Application:

Widely used for food, pharmaceutical, cosmetics, chemical and other plastic, PE, aluminum laminated tube filling and sealing.These products can be produced by this machine

Plastic and Composite Tube

Aloe Vera Gel

Aloe Vera Gel Eye Cream

Eye Cream Sunscreen

SunscreenAluminum-Plastic Tube

Hand Cream

Hand Cream Body Lotion Cream

Body Lotion CreamCustom-Made Tube

Facial Cleanser

Facial Cleanser

Wavy Shape

Makeup Remover

Makeup Remover

Euro Hole

Serum

Serum

Rounded Conners

Machine Options:

- Auto Refill pump

- Heating and mixing system for material hopper

- Air blow system for high viscous and sticky material

- Safety door

- Industrial water chiller

- 316L Stainless Steel Contact parts

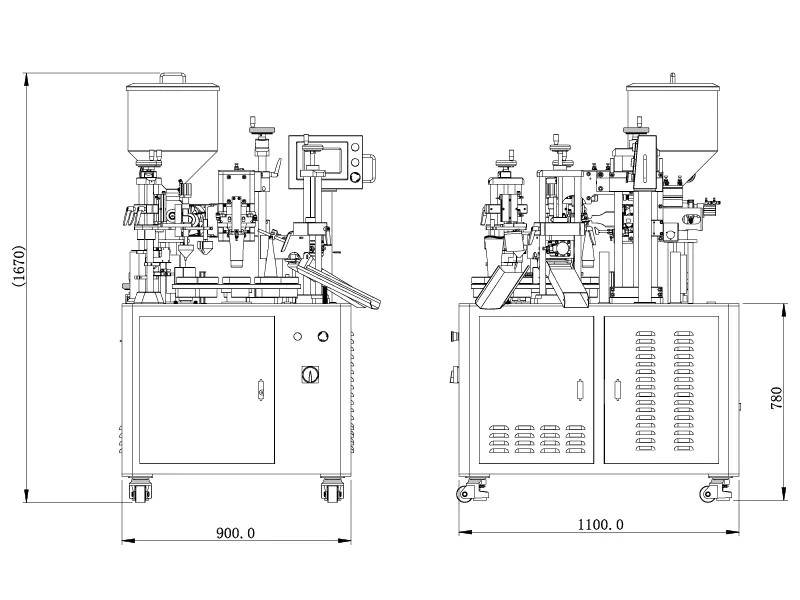

| Machine Parameters | |

| Model | HX-006 |

| Frequency | 20kHz |

| Power | 2600W |

| Power supply | AC220V/110V |

| Filling Range | A.6-60mlB.10-120mlC.25-250mlD.50-500ml |

| Filling Accuracy | ±1g |

| Capacity | 20-25pcs/min |

| Tube Diameter | 13-50mm |

| Tube Height | 70-250mm |

| Working Pressure | 0.6 MPa |

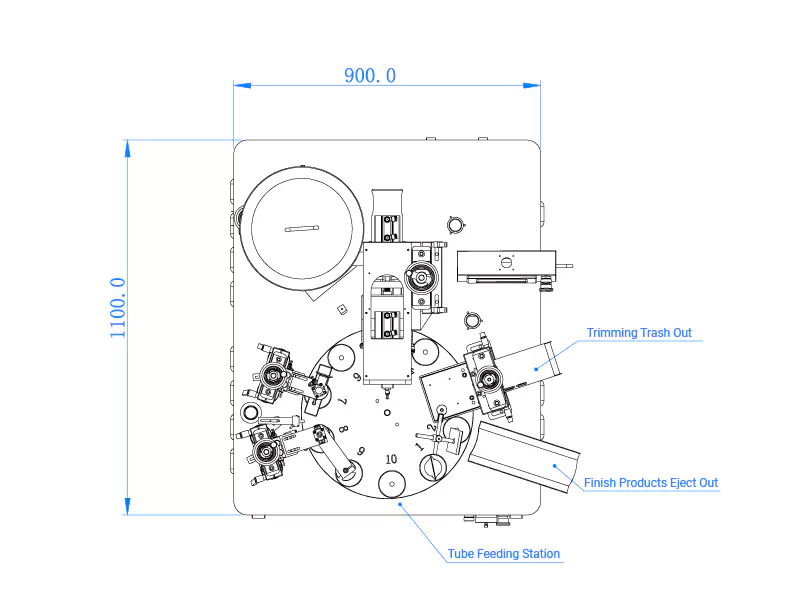

| Size | L900*W1100*H1600mm |

| N.W/G.W | 310kgs |

| Main part list: | |

| Ultrasonic System | Automatic Frequency Tracing |

| Benchmarking Electric Eye | Panasonic, Japan |

| PLC | Coolmay,CN |

| Electric Relay | Omron, Japan |

| Touch Panel | WEINVIEW,China Taiwan |

| Inductive Switch | SICK, Germany |

| Air Cylinder | AirTAC,China Taiwan |

| Solenoid Valve | AirTAC,China Taiwan |

| Motor | zhongdamotor CN |

| Partitioner | JOUDER,China Taiwan |

| Frequency Converter | DELTA,China Taiwan |

| Stepper Motor | Leadshine,CN |

Note: We don't provide emulsifying machine. This machine cannot make filling materials by itself. If you need, we could help you to contact manufacturer of emulsifying machine.

Note: We don't provide emulsifying machine. This machine cannot make filling materials by itself. If you need, we could help you to contact manufacturer of emulsifying machine.

Warranty:

1 year warranty from us (Excludes consumables). We also do repairs after the warranty period (Labour, shipping, and parts fee applied).Contact us

Email to us for catalogue and price list.