| Name and Specification |

QTY. |

Remarks |

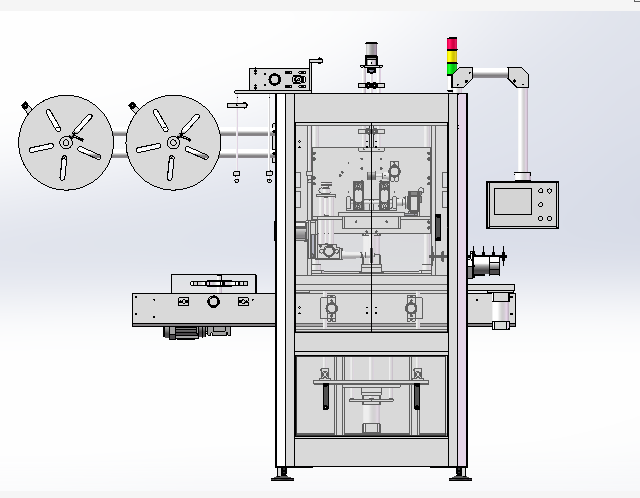

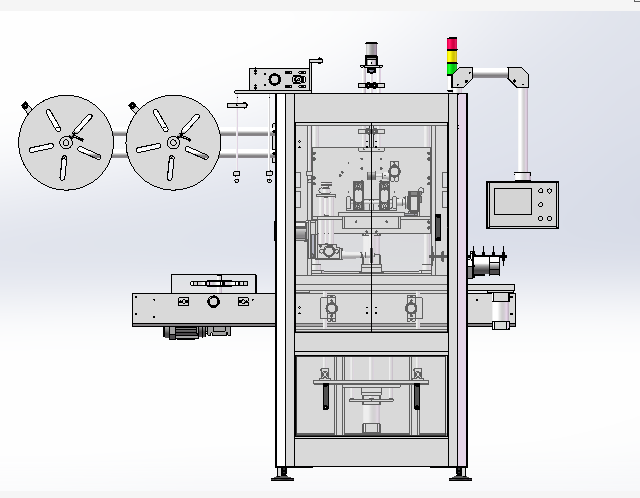

| Shrink Labeler (NC-100) |

1 unit |

Qualification rate: 99% |

| Chain Conveyor Belt |

7 m |

- |

| Steam Shrinkage Furnace |

1 unit |

Size: 2.4 m (stainless steel 304) |

| Steam Generator |

1 unit |

Power: 24 KW |

| Central Column |

1 unit |

- |

| Bottle Separating Screw |

1 unit |

- |

- Delivery Date: delivery within 30 working days after signing the contract and 30% down payment.

- Payment Terms: 30% T/T of the total advance payment, 70% T/T before delivery.

- Warranty: 1 year.

Configuration and Parameters of NC Series Standard Set

List of selected accessories (Annex I)

| Group | Device | Model | QTY | Brand | Origin |

|---|

| External framework group | Low power AC motor | 5IK60GN-CF.5GN25K | 2 | Chenggang, Taiwan | Taiwan |

| Label lift | Low power AC motor | 2IK 6GN-C /2GN30K | 1 | Chenggang, Taiwan | Taiwan |

| Brush down group | Low power AC motor | 180RA-CF | 1 | Chenggang, Taiwan | Taiwan |

| Feeder Group | Low power AC motor | 5IK90RGN-CF.5GN5K | 1 | Chenggang, Taiwan | Taiwan |

| Photoelectric sensor | CX-421 | 1 | Matsushita, Japan | Japan |

| Bottle carrying group | Low power AC motor | 5IK90GN-YF.5GN20K | 2 | Chenggang, Taiwan | Taiwan |

| Frequency converter | BFV0042G | 2 | Matsushita, Japan | Japan |

| Sub-bottle group | Low power AC motor | E2005SB | 1 | Chenggang, Taiwan | Taiwan |

| Frequency converter | BFV0072G | 1 | Matsushita, Japan | Japan |

| Brush group | Low power AC motor | 4IK25GN-C.4GN5K | 2 | Chenggang, Taiwan | Taiwan |

| Knife set | cutter head servo motor | MSMD042GIU | 1 | Matsushita, Japan | Japan |

| Disk servo drive | MBDDT2510E | 1 | Matsushita, Japan | Japan |

| Drive group | Drive servo motor | MSMD082GIU | 1 | Matsushita, Japan | Japan |

| Drive servo drive | MBDDT3520E | 1 | Matsushita, Japan | Japan |

| Electric Eye Frame Group | High speed fiber optic sensor | FX-551 | 1 | Matsushita, Japan | Japan |

| Photo Bottle Section | Photoelectric sensor | W9-3 | 1 | SICK | Germany |

| Electrical Cabinets | PLC | AFPX-C60T | 1 | Matsushita, Japan | Japan |

| Touchscreen | MT-6071IE | 1 | Weintek Labs | Taiwan |

| Switching power supply | MW-220-50-24 | 1 | Ming Wei, Taiwan | Taiwan |

| Switch knob | | 1 | Hong Kong | Shanghai |

| Relay | XK06-201/AHNA21 | 9 | Matsushita, Japan | Taiwan |

| AC contactor | S-N10 | 1 | Mitsubishi Japan | Japan |

| Circuit breaker | NF30-KC | 1 | Mitsubishi Japan | Japan |

| Terminal | | 1 | | Shanghai |

| Wire | | | | Shanghai |

| Three colors | | 1 | Shanghai Sky | Shanghai |

Configuration and Parameters of NC Series Standard Set

Technical parameters of the NC 100 shrink labeling machine:

| Host size | 2100L 1150W 2000H (mm) |

| This model contains 7 meters conveyor belt (including power, including chain plate). |

| Weight | about 400 KG. |

| Can be set bottle diameter range | X50-X95(mm), according to the product (non-standard customizable). |

| Bottle height | 80-280(mm). |

| Applicable bottle type | round |

| Set product temperature | 5℃+ normal temperature |

| Label length | 80-250 mm (Max). |

| Label thickness | 0.035-0.08 mm. |

| A power supply for V. | 220V |

| Standard machine speed | maximum operating speed of 6000 bottles / hour. |

| Energy consumption | 2 KW |

| Bottle shape or size at the same time need to replace the central guide post and sub-bottle screw, cutter head. |

| The conveyor belt is in the section where the standard machine is located, and its power is controlled by the standard machine. |

NC 100 standard mechanical configuration:

NC 100 standard mechanical configuration:

- Adjustable cutter head: original swing cut.

- Single positioning center guide column, label guide stable.

- Synchronous bottle separating device: bottle delivery is not easy to shake.

- Label brushing group: set standard accuracy is more accurate.

- Label control electric eye frame: original tail wing and electric eye combination to improve film cutting accuracy.

- Touch screen control box: more personalized operation.

Electrical configuration:

- PLC programmable controller.

- Servo motor.

- Servo drive.

- Frequency converter.

- Sensors.

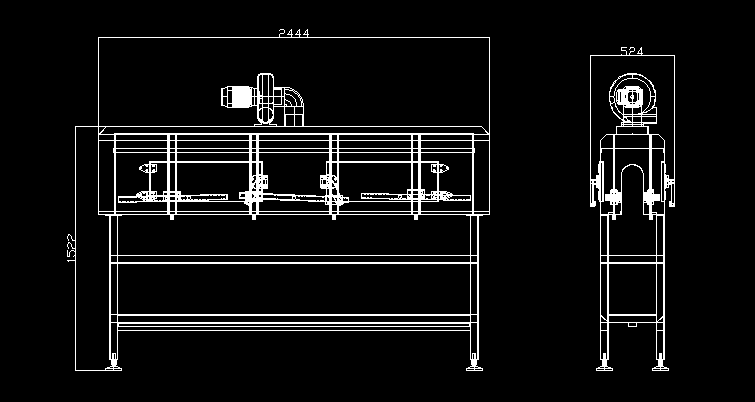

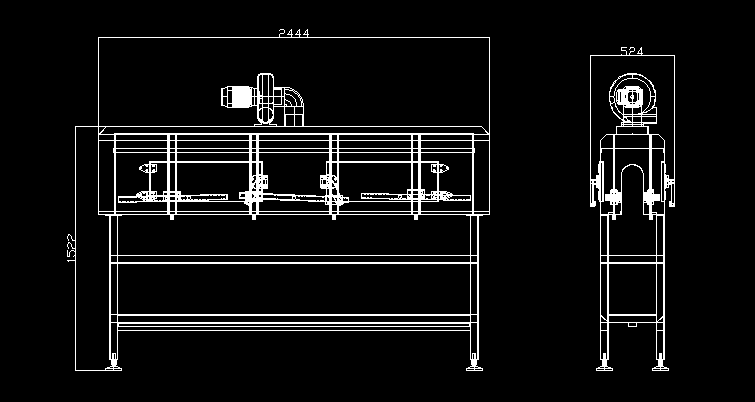

Steam shrinkage furnace:

Steam shrinkage furnace:

Technical parameters of ordinary steam furnace:

| Type | NC-2400-S |

| Shrinker Size | 2400L 500W 1600H(mm) |

| Steam Pressure | 0.2 Mpa – 0.4 Mpa |

| Temperature | 70-90℃ |

| Shrinkage Rate | 12000-15000 bottles per hour |

| Steam Consumption | KG/H 20-50 |

| Weight | 100 KG |

NC 100 standard mechanical configuration:

NC 100 standard mechanical configuration:

Steam shrinkage furnace:

Steam shrinkage furnace: